Finishing Resources

Finishing Resources

Fayetteville, Arkansas

Keith Baysinger: 719-661-9947

E-Mail: Finishingresources@yahoo.com

Website: www.FinishingResources.com

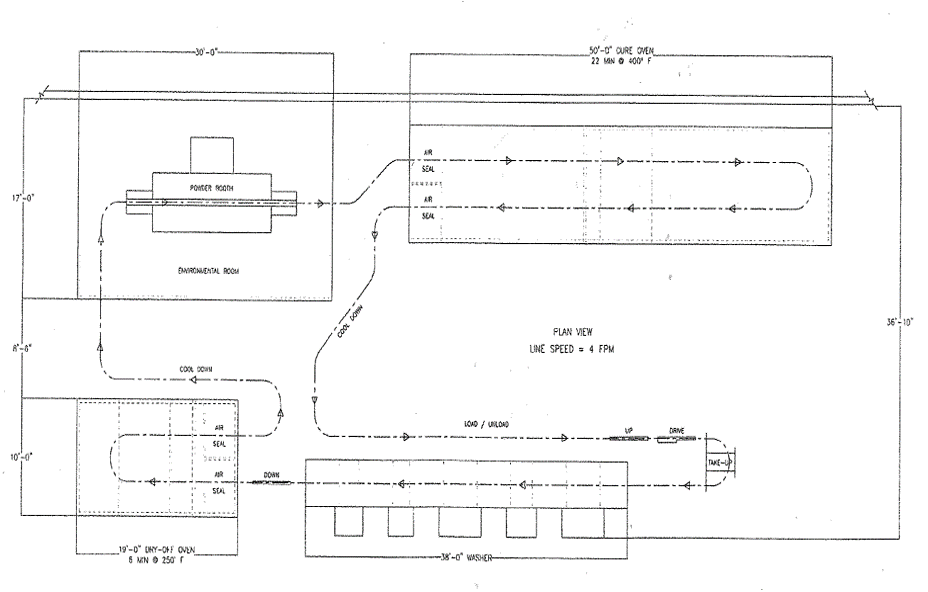

6 Stage SS Powder Coating System

Design: 30” W x 4’-0” H Opening, 10 FPM

scroll down for pics

Design Specifications:

• Part Opening: 30” W x 4’-0” H

• Maximum Product: 24’ W x 44’ H x 6’L (can be modified)

• Design Line Speed: 12 FPM (Variable <14)

• Condition: Very nice, Removed in 09/19

6- Stage Stainless Steel Washer

• Dwell Times @ 12 FPM:

• S1 – Clean (60 sec @ 140°F.); S2 – Clean (60 sec @ 140°F); S3 – Rinse (30 sec @ amb.); S4 – Rinse (30 sec @ amb.); S5 – Iron Phosphate (60 sec @ 130°F); S6 – Rinse (30 sec @ amb.) 12’ Drainbacks

• Stages 1, 2 & 5 – Heated with Hot Water Boiler (May be modified to Gas Imm. Tube)

• Haynes Pumps

• Dimensions: 12’-2” High x 10’-3” W x 48’ L

Dry-Off and Cure Oven –

• Dry-Off Oven.: 7’-9” W x 24’-10” L x 9’-2” H

• Dry-Off Oven Zones: 1

• Design / Max Temperature:, 500 Degree Peak Temp

• Time Cycle (Dry-Off): 6 minutes @ 10 FPM

• Time Cycle (Cure): 20 minutes @ 10 FPM

• Heating Gas fired Burner

• Oven Exhaust Fans, 2 per oven

• Adjustable Frames to move heaters closer to or further from part.

Cure Oven – Convection

• Dimensions: 17’ wide x 40’ long x 12’-0” high + BB

• Design / Max Temperature: <500° F

• Time Cycle: 5 minutes @ 10 FPM

• Heating Medium: Recirculating, direct- gas fired

• Floor-Mount Burner Box

• All Structure, Flashing, and Duct, Maxon Burners & Honeywell Controls, Oven Exhaust Fan and Entrance Air Hood Fan Provided

Conveyor System

• 600’ Long, enclosed track Conveyor System

• (1) Cat Drive & Take-Up, Oiler, (1) Lot Horizontal Turns

• Floor-Mount Structure

• Can be reconfigured as needed.

Installation services are available and may be quoted per customer request.

Contact Keith @ 719-661-9947 or Finishingresources@yahoo.com for more info or questions.

Contact Keith @ 719-661-9947 or Finishingresources@yahoo.com for more info or questions.

back to top