Powder coating over galvanizing presents it’s own set of problems to the powder coater but nothing we can’t overcome easily with a little knowledge on how to do it correctly.

One of the most durable protective coatings for steel is provided by applying a polyester powder coating over hot dip galvanized steel to provide a high grade architectural finish to steel items. Hot dip galvanizing is coating of metallic zinc bonded with steel to form a source of corrosion protection for steel.

What are Powder Coatings?

Polyester powders are thermosetting resins that are applied electrostatically to the steel surfaceand cured at temperatures around 180 deg C (about 400 deg F). This technology produces very uniform coatings that have an attractive architectural finish with excellent atmospheric weathering characteristics. In combination with hot dip galvanized coatings, the powder coated product ensures maximum durability for steel components, which will generally provide 50+ years rust free life spans in most architectural applications.

What are the problems with Powder Coating over Galvanizing?

Hot dip galvanized surfaces have been acknowledged as difficult to powder coat since the technology was first developed in the 1960’s. Industrial Galvanizers commenced research in this area in 1986 which culminated in the construction of a purpose built powder coating plant at its Hexham (NSW) site in 1988 in conjunction with its galvanizing operations there. The three main problem areas associated with the powder coating of hot dip galvanized steel products are:

Hot dip galvanized surfaces have been acknowledged as difficult to powder coat since the technology was first developed in the 1960’s. Industrial Galvanizers commenced research in this area in 1986 which culminated in the construction of a purpose built powder coating plant at its Hexham (NSW) site in 1988 in conjunction with its galvanizing operations there. The three main problem areas associated with the powder coating of hot dip galvanized steel products are:

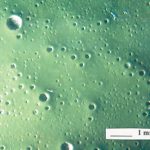

Pin holing of the coating

Poor adhesion

Incomplete curing of the polyester resin

Industrial Galvanizers of Australia investigates these problems, in conjunction with major polyester powder suppliers, resulting in the cause of these problems being better understood and polyester powder chemistry and plant procedures and design being modified to allow a consistent, quality assured polyester powder coated hot dip galvanized product to be supplied.

Learn more about hot-dip galvanizing

The problems associated with powder coating over hot dip galvanizing have not changed and inquiries are regularly received from throughout Australia asking advice following the failure of powder coatings over hot dip galvanized products.

Powder coating Pinholes

1. Pinholing: Pinholing is caused by the formation of small gas bubbles in the polyester coating during the stoving/curing cycle. These bubbles form small craters on the surface and are unsightly. They also produce holidays in the coating that reduce its long term durability, particularly in aggressive (marine) environments. The main reason for pin holing appears to be that the discrete polyester resin particles in contact with the galvanized steel surface do not fuse at the same time as those on the surface of the polyester powder film, because of the mass of the galvanized steel * 1 , and the time taken for it to come up to fusion temperature. Specially formulated resins with ‘degassing’ agents have been developed to alleviate this problem by delaying the onset of fusion of the powder. Pre-heating the work in a pre-heat oven prior to powder application allows heavier hot dip galvanized sections to be powdercoated and deal with the problem of pin holing when used in conjunction with ‘degassing’ grades of polyester powder.

* 1 Note : Hot dip galvanized items tend to be of heavier section thickness than other steel items, typically sheet steel, that are powder coated. These items thus take longer to reach oven temperature because of their greater mass.

Poor adhesion causes peeling

2. Poor adhesion: The final stage in the hot dip galvanizing process involves water quenching of the work, frequently in a weak sodium dichromate solution. This process cools the work so that it can be handled and passivates the surface of the galvanized coating to prevent early oxidation of the surface.

The presence of a passivating film on the surface of the galvanized coating will interfere with the zinc phosphate or iron phosphate pretreatment, and in many cases, render these pre-treatments ineffective.

It is essential that hot dip galvanized items are not quenched * 2 after galvanizing. This ensures that the zinc surface is in a highly reactive state to accept the pretreatment applied in the powder coating process.

* 2 Note : It is equally important that the unquenched hot dip galvanized surface is kept clean and dry prior to powder coating. If wet with rain or dew, it will rapidly oxidise and again cause coating adhesion and quality problems.

3. Incomplete curing: Polyester powders are thermosetting resins that cross-link to their final organic form by being maintained at a temperature (typically 180 o C), for about 10 minutes. Curing ovens are designed to provide this time at temperature combination. With hot dip galvanized items, with their heavier section thickness, it is necessary to ensure that sufficient stoving time is allowed to meet the curing specifications. Pre-heating of the heavier work will assist in accelerating the curing process in the curing oven.

SPECIFICATION FOR POWDER COATING OVER HOT DIP GALVANIZING

The following specification is recommended:

- Hot dip galvanize and do not water or chromate quench

- Remove all drainage spikes and surface defects

- Powdercoat within 12 hours of galvanizing. Do not get surfaces wet. Do not leave outside

- Keep the surface clean. Do not transport uncovered loads. Diesel fumes will contaminate surface

- If surface contamination has occurred or is suspected, clean surface with proprietary solvent/detergent designed for pre-cleaning prior to powder coating

- Use zinc phosphate pretreatment if highest adhesion is required. Surface must be perfectly clean. Zinc phosphate has no detergent action and will not remove oil or soil.

- Use iron phosphate if standard performance is required. Iron phosphate has a slight detergent action and will remove small amounts of surface contamination. Best used for pre-galvanized products

- Pre-heat work prior to powder application

- Use ‘degassing’ grade polyester powder only

- Check for correct curing by solvent testing. Adjust pre-heat and line speed to ensure full cure.

SUMMARY

Properly applied powder coating over hot dip galvanizing will give exceptional performance. Many architectural projects done with this process in 1988 remain in excellent conditions today.

One of the first ‘heavy’ powder coating projects undertaken in Australia – pedestrian bridge rail on the Janet Street

overpass on the Wallsend-Sandgate expressway link, hot dip galvanized and polyester powder coated in 1989 still in excellent condition in 1997.

Related Resources

- Building Environment Enclosures

- Engineered Buildings

- Powder Coaters Corner

- Powder Coating Industry Research

- Contact